Did you know that over 300 000 tons of wooden pallets are discarded into landfills in North Carolina alone each year? Considering that the pallet industry consumes around 4.5 billion feet of hardwood annually (which is often made from expensive wood such as teak, hickory, etc.), this is a lot of potentially valuable planks going to waste. In this article, we will discuss how you can go about using pallet wood for flooring in an easy, actionable way. Let’s get started by learning how locating pallets for your floors.

Did you know that over 300 000 tons of wooden pallets are discarded into landfills in North Carolina alone each year? Considering that the pallet industry consumes around 4.5 billion feet of hardwood annually (which is often made from expensive wood such as teak, hickory, etc.), this is a lot of potentially valuable planks going to waste. In this article, we will discuss how you can go about using pallet wood for flooring in an easy, actionable way. Let’s get started by learning how locating pallets for your floors.

Great Places To Find Pallets For Your DIY Flooring Needs

When you start collecting pallets from businesses, individuals and even landfills for your floors, make sure that you get permission. Some stores will not be able to give out their pallets for free for a variety of reasons. Collecting all the pallets that you need for flooring a room or home might take awhile so it’s best to consider your pallet collection as a hobby as you slowly build up your stock. Here are a few good places to start looking:

- You can find pallets in most grocery stores, department stores and warehouses. Any place that receives large shipments of products on a regular basis will likely have a lot of pallets at their disposal. You can call up a couple in your local area and ask them if they have any wooden pallets that they are getting rid of. In most cases, they will tell you that they often throw them away and you can pick them up for no charge.

- Small hardware stores, new businesses that just opened and small garden stores generally not have a systematic way to get rid of their pallets and will generally have no problem if you want to take them off their hands.

- Landfill sites often contain large numbers of pallets that are discarded on a regular basis. While this is definitely an option, just keep in mind that it’s often difficult to know where they were used before. This can pose a safety issue which I will elaborate on this a little later in this article.

- You can also purchase pallets from most hardware stores. The downside of this is that this will cost you money and this might not really be worth your while, especially if you are considering doing DIY pallet flooring to save yourself some money in the first place.

How Much Will Pallet Flooring Cost Me?

It should cost you less than around $200 for a large area, provided you were able to collect the pallets for free. Your only real costs will be your time (which is valuable and cannot be ignored), any tools that you may need to buy or hire, the underlayment (to help with moisture control) and any hardwood floor finishing that you might want to apply over the wood (highly recommended in most cases).

It should cost you less than around $200 for a large area, provided you were able to collect the pallets for free. Your only real costs will be your time (which is valuable and cannot be ignored), any tools that you may need to buy or hire, the underlayment (to help with moisture control) and any hardwood floor finishing that you might want to apply over the wood (highly recommended in most cases).

Considering that a decent hardwood floor (with installation) will often cost thousands, this is a very good price, even though it does require a lot of time and effort on your part. I have read countless articles on the web that profess that “time is free” but I completely disagree with that statement. An easy way to understand how much your time is worth is to figure out how much you would earn per hour if you got a second job (even if it was just temporary and was only to pay for a new floor). On the other hand, if you are excited to build a floor using pallets and it’s more of a family project, then that’s a different story.

How long will it take to collect all the recycled pallets? Well, that figure is definitely up for debate. If you find a large supply of fairly decent quality pallets, it could take you a weekend. If you have to search high and low for them, it could take you a couple weekends. On the other hand, if you were just looking for some spare wood to repair your broken hardwood floor, then that might just take one trip.

The Average Lifespan Of Recycled Pallet Flooring

The longevity of your floor really depends on how much foot traffic it will receive on a daily basis. However, this is nothing to be overly concerned about. Even with regular activity, provided you maintain your floors, you will only experience a very slight deterioration over time. However, wooden pallet flooring does have a unique advantage. If a section gets damaged, its super easy to replace that area with leftovers from when you built the floor! Even if you didn’t have any leftovers, you could easily find more and do a DIY replacement in an hour or two. I personally feel that this is a major advantage that people often overlook when discussing this subject.

If you want to keep your floors looking great, you can also instruct family members to take off their shoes before walking on your floors and stop the dogs from running over it each day. Additionally, I highly recommend that you finish your pallet wood planks with a decent quality product (more on this a little later).

Making Sure Your Pallets Are Suitable

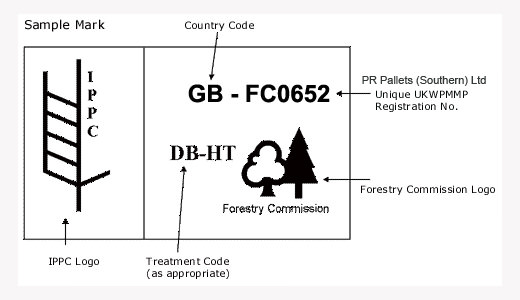

Firstly,only use wood pallets that contain an IPPC logo and avoid ones that have reference to “MB” (Methyl-bromide) or “CT” (Chemically Treated). I also recommend skipping colored pallets as they often contain formaldehyde. If you want to add color to your floors, you can always paint your wood floors afterward. Chemicals might do a great job at keeping insects and some bacteria at bay, but it’s definitely not something you want in your flooring at home. Ideally, you want the pallet to contain the “HT” stamp, meaning that it was “Heat Treated”.

Firstly,only use wood pallets that contain an IPPC logo and avoid ones that have reference to “MB” (Methyl-bromide) or “CT” (Chemically Treated). I also recommend skipping colored pallets as they often contain formaldehyde. If you want to add color to your floors, you can always paint your wood floors afterward. Chemicals might do a great job at keeping insects and some bacteria at bay, but it’s definitely not something you want in your flooring at home. Ideally, you want the pallet to contain the “HT” stamp, meaning that it was “Heat Treated”.

I know it is possible to sand (don’t forget to always use a respirator) and seal the pallet planks to make them safer for indoor use but rather take my advice and stick to pallets that are heat treated (no chemicals), sourced locally, uncolored and are not involved in the transportation of food. As a rule of thumb, if you cannot confirm that the pallet is safe, rather don’t use it. I highly recommend this pallet safety article from 1001pallets, check it out when you get a chance.

Special Offer: Get Some Help With Your Pallet Floor (United States Only)

We have partnered with Networx to help our readers get affordable quotes to help with their pallet flooring project from contractors near them. Simply

, fill your details and you will get a few within 48 hours. There is zero obligation and this is 100% free. 🙂How Many Pallets Should Be Collected?

A single pallet usually can be stripped (more on in the next section) to provide about two square yards (1.1 square meters) of wood planks. This is presuming that the entire pallet is in a fairly good condition as outlined in the previous section above. Once you have measured the size of the room, that will help you get an idea as to how many pallets you will need to complete your flooring project.

Methods To Break Up Pallets And Remove The Nails

Breaking up the pallets is easily one of the hardest parts of the project (besides actually finding them). You have a couple options available:

- Use a claw hammer – A regular claw hammer works but may break it as it’s not ideally suited for this task.

- Use a crowbar (ply bar) – This is a good option (if you have one), just be careful that you don’t break the planks when using it.

- Use a pallet breaker – Although I haven’t personally use it, Instructables has a DIY pallet breaking tool guide that looks effective for breaking pallets up.

- Use a circular saw to simply cut the pallet into smaller planks, thus eliminating the need to break it up using tools. This method is super fast, but you won’t get very long pieces of wood.

Removing the nails is also a very important step in stripping the wood pallets. Make sure that you pull, yank, unscrew, hack out, etc. any metal bits that may be embedded in the wood before moving on.

How To Make A Floor Out Of Pallets (Preparation)

How To Install Pallet Flooring Correctly (DIY)

Finishing Your Pallet Wood Floor (With Style)

In conclusion, although pallet hardwood flooring may not be suitable for all rooms and homes, it is certainly worth considering as a flooring option. It provides a way to give your floor a unique and memorable look and can potentially save you a lot of money when compared to other flooring options. Provided you follow safe collection practices and are willing to spend quite a bit of time and effort (and follow the guidelines in this article), you should be very pleased with the final outcome. If you have any pallet flooring ideas, please feel free to share them with us in the comment section below.

Thanks for reading this article! Please considering sharing it with your friends and family. 🙂

Bill Reed

Latest posts by Bill Reed (see all)

- Acacia Flooring – Your Ultimate Guide - January 20, 2017

- Refinishing Hardwood Floors, The Ultimate Guide - October 6, 2016

- Walnut Flooring, Your Authority Guide - July 28, 2016

Just a quick question, are pallet floors hard like hardwood floors? I’m tossing up the idea of doing pallet floors in my entrance area but I’m worried they will be soft and get wrecked easily. As an entrance area is a high traffic area its a big choice to make.

Hi Sam! Some pallets are made of quality hardwood, those are the ones that you should be looking for. Since it is high traffic, you will want to avoid any soft woods that you find, especially with that high traffic area. In the end, your project is a viable one if you are willing to put in the time / effort.

Bill how durable is pallet floors I was told by aan who works in pallets it’s junk won’t hold up is there truth to this

Hi Kim, it really depends on what wood the pallets (that you deconstruct) are made of. It they are made of a soft wood, then yes, they won’t hold up. However, if you hand pick good quality pallets, you can get a hardy DIY floor at a fraction of the cost.

I am thinking about using pallet wood to floor my garage, in which I have a few tools and do woodworking. The floor is concrete, so I cannot nail into it. Wonder if I can do a direct glue-down wood over concrete, and use parquet glue to hold them down.

Hi Cliff, not too sure about the parquet glue but yeah, industrial strength glue can hold the pallet planks (provided they are not warped or anything of course) down.

Putting the pallet planks over osb recommended. It’s mostly level, but a few dips. How to level? I’m thinking of using black screws, good idea?

Hi Michael, you could do that. I recommend using 1/16″ felt (if that is the difference in your uneven floor) or you can get some decent self-leveling OSBm just read the instructions first because they sometimes have a minimum thickness. Hope that helps you 🙂

If putting pallet flooring on concrete, like in a basement, how would you attach it to the ground? Would you need a sub-floor(plywood) with a moisture barrier under that? Can it only be glued and if so what do u recommend?

Hi Bill B! Yes, you are 100% correct, that is the best way. You can glue it, just use industrial strength glue that has been specifically made for this purpose, not just anything you find at the shops. Good luck!

tip given to me by a contractor is chipboard….that super thin cardboard you get cases of beer in (or soda) it wont expand its moisture resistant and you can stack up as much as you want or even feather it if your depression is big enough. I used it when i installed a laminate floor (which i plan to pull out and put in pallet floor as soon as i acquire enough pallets. It worked great with the laminate and plan to use it when i do the pallet floor

Hi Patrick! Thanks for responding to Michael and providing the community (and myself) with this great tip. Although I have never done this before, I think that is super epic!

I got a whole bunch of pallets from a workshop down the road. I disassembled them and noticed that some are very bent and curved. Is there a way that I can straighten them again or should I just right the curved ones off?

Hi Jesse! It is possible to straighten them but it is quite a mission. Since we are dealing with pallets in this case, I suggest that you toss the inappropriate ones (in this case, if it is warped, etc.) and rather spend your time collecting more. Hope that helps!

Thanks for the informative article. Any advice on putting this down on a concrete slab? What would the best way to attach the pallet boards to the floor be? There is carpet now, but once we collect enough pallets, I’d like to yank up the carpet and put down a pallet floor!

Hi Bryan, apologies for the slight delay on my response, I have been ill. To attach it to concrete, I suggest installing a decent subfloor first and then you can use industrial strength flooring glue / construction adhesive to stick it all down (including the pallets). It will work really well. Would love to see some pictures when you are done, if that is cool with you. 🙂

Hi I was wondering what kind of underpart to use since I have plywood down and wanted to use the pallets for the flooring

Hi Colleen! You can use any hardwood underlayment (your local flooring shops should have them). Check this article for the recommended thickness and make sure that it is properly attached before laying down the pallet planks. Hope that helps, will love to see the project when it is completed, if that is alright with you? Have a good one!

I’m wondering how to smooth the floor, so there aren’t splinters and such. would I use a floor sander? what would your suggestion be?

Hi Darlene! I recommend that you use a belt sander (make sure you use the correct grit of sandpaper). You can do it by hand but it will take a very long time so I don’t suggest doing that (unless it is a very small room hehe). Hope that helps, please share your progress, would love to see it.

Love the article! I’ve been making several things from pallet wood and I’m taking it to the next level with a pallet wood floor! I have a couple of questions…. First, how do you fill the holes where the nails were or do you just leave them open? Secondly, I use a reciprocating saw to cut my pallets apart by sliding a metal cutting blade behind the nails and cutting the top/bottom boards away from the pallet brace boards. I am left with smooth surfaces on the back and the normal nail head (usually embedded) on the front. Would I HAVE to remove the nails? The floor will be coated with polyurethane several times so I don’t think I am running a risk of snagging my toes on nail heads…… Or am I?

Hi Katiy! You can use some regular wood filler, just try match the color of your wood (ideally). You don’t have to but unless you are specifically trying to achieve that look (with the nails), rather just remove them. I know it takes some time but it is worth it, don’t want it to cause potential issues later. Hope that helps!

Great article. Redoing the crummy job of tiled kitchen with pallet flooring. What glue,nail or screws do you recommend.

Hi Mark! Thanks for your kind words! I recommend a 3 inch floor nail (or power cleats) to attach it to the subfloor. Alternatively, if you decide to go with the glue route, just make sure it’s industrial strength glue (construction adhesive) to ensure it stays down. Hope that helps, please share this article on Facebook if you appreciate my help 🙂

Thank you for the article, very informative! I am putting pallet wood over osb. I have my pallet wood separated and the osb and underlayment down. I have started laying some of the planks down to practice and decide on a pattern and such. I am very excited to get this floor completed. The room is 11’x12′. It has taken me several months to get this far, starting with ripping nasty carpet out. I am disabled and short of help or finance. I was planning to use wood screws to save my wrists/arms and thought it would stay longer. My brother used nails on the boat dock he made with pallet wood and has had an issue with nails working their way out…but maybe because it is moving on the water all the time? I don’t see any recommendations on using screws anywhere. Would this be a mistake to do with flooring?

Hi Annette! Thanks for your kind words! Yes that might be the reason but a floor would never have that amount of movement. You can use screws, provided they can attach effectively to your subfloor. If that is the case, then by all means, use them. Hope that helps, please share some pics when you can!

Hello, I have a source where I can get pallets at a very inexpensive price, and this idea intrigues me. My biggest question is, how do I get all wood to be the same thickness? Do i purchase a planer? or what? Thanks for your detailed instruction btw.

Hi Chopper! Yes, but I wouldn’t purchase one honestly, as that can be a bit expensive. Ideally take it to a wood factory and pay them to do it for you or alternatively, perhaps rent one if that is a possibility in your area. I suppose you could sand them but yeah, that is going to take a while lol.

Great artical, I love the look and would like to do this. My house is on a concrete slab, do I need to put in a plywood subfloor or can I glue it to the concrete?

Hi Paul! Thank you for your kind words! There are a number of benefits to installing a subfloor and I recommend that you do that regardless, it doesn’t have to be plywood though. If you are determined to attach it directly, yes you can use industrial strength glue or cleats to keep them firmly attached to the floor. Hope that helps!

I was just recently given a manufacture double wide from a family member as a wedding gift. The place needs a lot of work and I’ve been toying with the idea of laying pallet wood as the flooring in some of the house but I am not sure that is possible or not? Since it is a manufacture home? If so would ply wood as an underlying work and the put down a floor muffler ultra seal flooring underlayment and then the wood pallet boards?

Hi Madison! Yep, that should work very well. Although I haven’t done pallet flooring in a manufacture home before, I don’t see it being a problem. Let me know how it goes, will love to hear your progress and thoughts along the way.

Can you install the pallet boards over the old laminate floor or should it be removed

Hi Darcy! You can, but I suggest that you remove the laminate first, will be better in the long run. Hope that helps, thanks for stopping by!

Going to do a wood floor with the pallette how doors I finish it?

Hi Lapez, I have just finished writing an article on wood floor refinishing. It will be publishing it in the next two days and will email you the link, it should cover every question you might have about the topic so stay tuned 🙂

What did you use for the sealer and where do you find it?

Hi Lynette! Most finishing products will be able to “seal” the planks so don’t worry about purchasing a separate product. There are a bunch of brands that are available, some depending on geographic regions. My suggestion is that you ask your local home improvement store, they will be able to help you with the specifics and the pros and cons of each. Thanks for your comment!

i’m thinking about doing this in my bedroom it’s about a 120 square foot bedroom i’m gonna use the construction glue on the back side what size nails or screws should i use to attach the floor. im doing this on a tight budget

Hi Charlie, I suggest you use a 3 inch power cleat, the link is under the “how to install..”, step #3. Hope that helps you, thanks for the comment! P.S: Don’t forget that glue is also an option!

I have a whole bunch of pallet wood that has never been attached to anything. I want to put in in an old house that the floors are paint ply wood. Can I install the planks and then sand with a belt sander or sand each plank individually? Do I need to sand the painted floor? I am worried about dry rot?

Hi Duane! I suggest that you sand each plank individually, especially since they have been unattached. Attach them to your floors as per this guide and then use a belt sander to even the floor out a bit (ideally you should just pallet that is around the same height). Apply your stain, then apply your finish and you will be left with gorgeous floors, after the time and effort has been put in of course 😉 Hope that helps!

I would appreciate a peek into your new article (link) on finishing. I’m at the beginning stage of collecting but before I get started, I want to know everything….down to the last knuckle!! Great read…..truly appreciated!! Looking forward to more?

Hi Cowgirl! It is a pleasure! Things got a little hectic so it is not posted yet but I have the final draft ready and should get it up this week. Thanks for sticking around! 🙂

Waiting patiently, no hurry!! Just let me know when up??

Thank you for writing an excellent article. Even the replies to the questions are really helpful! 🙂

Hi Glynis! It is a pleasure, I enjoy helping the community! Please consider sharing this article on FB 🙂

I did! 🙂

Ho I have been collecting pallets and breaking them down for months I plan on doing a 300 sq.ft. addition with them, just wandering what is the minimum thickness of the boards you would suggest.

Hi John. Honestly, I would just go through your pallets and look for the average thickness as it doesn’t matter too much. The key is to make them all the same though so if half is 0.8 inches and the other half is 0.7 inches, you would need to make them all 0.7 inches. Hope that makes sense. Please share your progress, would love to see some before and after pics if you get some time. Good luck!

I know that pallets can have the possiblity of been infected with fugi or bacteria. Do I need to treat all my pallet planks before I use them?

Hi Joanna! You can treat them but make sure that it is done properly. I personally recommend trying to stay away from pallets that could be infected. Check the IPPC logo and find out what they were being used for before collecting them. Hope that helps!

Thank you for the wonderful advice! I am remodeling an old school bus into a mobile home, and I am using pallet wood for many parts of the house, so I was delighted to come upon this post! I am wondering if you have any advise for attaching these floors to a metal base. I would prefer not to lay down plywood first (I have a very low budget) but I would love to make this work! Thanks!

Hi Zea! That sounds exciting, please share pics when you are done! I must admit, I have never attached pallet to a metal base before but industrial strength adhesive should work, make sure you find one that will work with the metal. Good luck!

Hi again Bill,

I have decided to plan all pallet boards for my 300sq.ft addition to .5″, have the first batch ready to put down but still in process of planning the majority of the boards…when I go to put them down the subfloor already had felt paper over top of it (under the current carpet) would that be suitable for the moisture control or should I still use another of Visquene or plastic, also for future projects or replacing boards in the future I was thinking of laying 1/4″ luan or I seen you mention even self leveling OSB, does that seem reasonable or you think it’s adding unnecessary time and money into it?

I would like to know the same thing. I don’t want to glue it to my osb and the down the road try to pull it up. I believe that would ruin my osb. Thank you.

Hi Melanie! If you lay down some OSB, then you can simply use some quality floor nails instead. That way it can be removed easier. Hope that helps!

Hi John! Sorry I somehow missed this message, my bad! I recommend that you get some of that self leveling OSB, it will work great and will be worth the money. I am not saying that hte felt won’t help, but it won’t be sufficient, especially for noise reduction.

This is so very helpful. Thank you! I looked for my question in the comments first, but only found half of the answer. I tried. 😉 My husband and I are very interested in doing this to our whole house (it’s only 900 sq ft) one room at a time. But we’re working with a slab foundation. I read that you recommend laying down a “decent subfloor”. Could you advise the cheapest quality subfloor option? I’ve read plywood works- is that right? Also, would the moisture barrier go directly on the slab? Or on top of the subfloor? If it goes on the slab, how would we attach it? Thank you for your time! I promise I’ll send you pictures when we’re done! 🙂

Hi Jamie, thanks for checking the existing comments first hehe 🙂 Plywood will work well and it is affordable. The moisture barrier is usually below the subfloor, and when you attach the plywood to the slab, it will keep it in place. I suppose you could glue it a bit but not usually necessary. Hope that helps, please share this article on Facebook if you don’t mind 🙂

Thank you!! 🙂 I’ll share this when I share the finished pictures of the project. I’d do it sooner, but I don’t feel like arguing with my unimaginative/uptight/boring/namebrand friends. 😉 We’re excited to get started! Thank you again!

Hi Jamie, best of luck! Hope everything works out!

Thank you for the extremely well done web design (the tabs, etc) as I know that takes some creativity too. I’m planning on doing our upstairs hallway and with 3 kids and a dog, I like the fact that it will be easier to repair the wear and tear. I also appreciate that time is still a commodity as this gets over looked. Thanks again!

Hi Lauren, it is a pleasure! Yeah these articles do take ages, sometimes more than 20+ hours so thanks for your thoughtful words 🙂

Hi Bill,

I too read the comments regarding the cement slab install. Just want to clarify…(first time doing any flooring myself – figured this was easiest and I love the pallet look). Anyways, is there a specific moisture barrier I should use? Also would I use the adhesive you mentioned to attach the subfloor to the moisture barrier, then the adhesive to attach the pallets to the subfloor? I greatly appreciate your time!

Hi Tisha! Any quality moisture barrier will work, just don’t go cheap on this. Yes that sounds fine, you can also use power cleats to assist if that is not working well enough. Thanks for the comment!

Hey bill i was just wondering did you do tongue and grove on the pallets or not

Hi Chase, I didn’t but feel free to do it if you want. I find that industrial strength glue, power cleats and a decent subfloor does the job perfectly.

Do I need to put underlay down before I put the pallet wood floor in

Hi Jake, yes I recommend it. Hope that helps!

When laying the boards down do you put them up against each other or do you leave a little space? If a space is needed what do you use for spacers?

Hi Tiffany! You can stack them together with a tiny gap between them, no need for spacers.

We’ve found a source for oak planks that are still bundled on pallets and are considering using them to create flooring. Do we need to use spacers between planks to allow for swelling so they don’t buckle?

Hi Sandy! Flip, that is a goldmine right there! You can leave tiny gaps between them to allow for that if you wish, just don’t let them become dust traps hehe 🙂

Hi Bill, my wife and I bought a 150 year old farm and with the exception of one room upstairs, the whole house is the original pine barn board floors, The living room is an addition and is more recent pine flooring. We are thinking of doing the remaining room in pine pallet boards. I have lots collected already as I am a hobby woodworker and build with pallets exclusively. Thoughts? There seems to be quite a range in quality and hardness when dealing with pine.

Thanks

Glenn

Hi Glenn! I think it will turn out nicely! Yeah they will, you will need to try select planks of similar thickness and quality. If that is proving difficult, you can usually get them planed at a relatively low cost (if you don’t own one). Hope that helps, let me know how it goes!

Hello, great article, thanks! We replaced our wood privacy fence recently and saved all of the planks that were remotely flat and sturdy still. Would it even be possible to re-use this as a floor with proper bleach cleaning, sanding/planing/ jointing?

Hi Crystal, glad you liked it! Yes, provided they are not made out of cheap wood. You will also need to plane them all the same height, but either way, it will be much cheaper than buying all the wood. Good idea!

have a thickness planer and can borrow a jointer so I should be good thanks. Happy New year.

hey thanks for the article, answered a lot of questions i had. the one question i still have, i have a old house and they used wood planks right on joist with nothin else between th floor and ground. i really didnt know what i should put down or do i need a subfloor as going with pallet floor was part of my saving money plus a cool look. i really didnt know what to do there and i was putting insulation under the house, without a subfloor would insulation be sufficient or should i try a different route. the only other floor i was considering was burnt plywood, which also would look good. what is your opinion on this issue?

Hi Adrienne, I always recommend that you have a subfloor. I have had some experiences in the past with people who refuse, just put down waterproofing and I can assure you, it did’t work out well for them. Burnt plywood does look good, if you can find it affordably, go for it.

We are in the process of putting down a pallet floor in our kitchen. My husband tore apart, cut and planed the boards. We’re finding that they’re not perfectly straight and we have some small spaces. Is there a sealer that we can use to seal up the boards and small gaps so no liquid will go down into the cracks? Or is there a filler that we can use to fill up the gaps? Looking for any advice to seal up as much as possible so that we don’t have any issues with rotting boards or mold/mildew down the road.

Thanks!

Hi Jennifer! If the gaps are small, then yes, rather go with a quality wood filler. Once you are done, you will be finishing the floor which will prevent that. Check out my article on the subject, I posted it a couple weeks back. Hope that helps!

Hey Bill,

Is it recommended to apply the pallet flooring on a plywood subfloor? If so, which method do you prefer to secure the pallet wood, nail or glue?

Thanks,

Hi Cory! Yes, it is necessary to have a subfloor, if you want a quality result in the end. Either way is fine, both work well. Thanks for stopping by!

How thick should the pallets be planed to be used as flooring?

Hi Mike, 0.5 inches is the sweet spot. However, it doesn’t matter too much, just choose the height and then make sure they are all the same.

Hi bill,

I’m from Canada here winters and summers can get harsh. I’m just wondering if glueing and nailing down the pallets will warp faster with the amount the house shifts threw out the seasons. Or should I do a toung and grove and make it a floating floor if that’s possible?? Thanks

Hi Luc! It is possible to do a T/G setup with pallets, it just requires the right tools. If you can do it, then that would probably be best, based on your description. In saying that, provided you leave enough breathing room between them, you should be fine. Maybe consult a local flooring company in Canada and get specifics about how much wood planks move during seasonal changes. Thanks for stopping by!

I am purchasing my first home (as we speak) and plan to replace all carpet and linoleum throughout the entire (1100 sq/ft) house with pallet floors. I am a Maintenance and Facilities Manager and an electrician of almost 20 years. I thoroughly enjoy wood working and am (usually) fairly successfull in my endeavors, and have a readily available supply of KD/HD pallets, as we ship internationally.Is there any additional tips you can give not previously covered in the article, that would assist in this lengthly task? I do want to thank you for your time and advise…. reading it made me feel very comfortable with my choice! Mainly because the amount of pallets ebtering the landfill is absolutely absurd, with their potential and our already declining woodlands, but also that it seems pretty reasonable in retrospect.

Hi Jeremy! Well done, that is quite the achievement and very exciting (and scary at the same time hehe). In addition to the article, maybe aim for a 0.5 inch height for the pallets and make sure you are putting them on a decent sub-floor. As for finishing it, you can check my refinishing article for tips. I know that it will be the first coat, but the information is similar. Hope that helps and good luck, let me know how it goes!

Thanks for the info Mr. Reed, Since the pallet pieces are not tongue and grooved how do you insure a level floor? Or in the end a total sanding is needed?

Hi Byron. Good question! I suggest installing a plywood subfloor (nailed to the joists), which the pallet boards can be attached to. You can skip the subfloor but I don’t recommend it. Hope that helps!

Thank you for the informative article and replies. Have you thought of setting up a recycled pallet wood flooring product shop where you would: 1) source and disassemble the pallet wood 2) cut them into uniformly straight rectangular or square planks 3) put each plank though a planer to make them all the same thickness 4) put each plank through a belt sanding machine to make them smooth 5) pre-finish each plank with sustainable finish, and then 6) sell the resulting planks by some $ per sq. ft? Do you think this could be done and sold to consumers for less cost than traditional wood flooring? Thanks.

Hi Eric! That is actually not a bad idea! However, definitely would have to run the costings. Also the issue would be that as soon as they know the pallet is for another commercial use, the price gets jacked by quite a sizable amount hehe. But yeah, will check the data! If anything, it will save a ton of wastage and that’s a bonus in itself. Thanks for the comment!

Hey Bill.

I’m looking to put in pallet wood flooring in my wife’s craft room. I pick up pallets on construction sites. However I wouldn’t think it would be a good idea to lay down wet/damp planks. How long would you suggest storing them indoors to dry before installation?

Hi Craig! Yeah they will need to be very dry and that is not going to happen by leaving them in a locked shed or something like that. If you have some good ventilation and the weather is nice and hot, a couple weeks should be more than enough. Just make sure that they are not moldy or anything like that, more info is in this article. Hope that helps!

We want to put a pallet floor in the basement, a contractor friend said it would lower the value of the house. I have never heard that before, what are your thoughts

Hi Brian, it all depends on how it is installed and the quality of the pallets used. If you think about it logically, would a new hardwood floor made from quality wood that are all a uniform height, with a great finish, lower the value of the house, just because the wood came from pallets? Unlikely. On the flip side, if you just use rubbish wood, don’t install it properly and leave it unfinished, then of course it will look horrid. Hope that helps!

Can you take fence boards and do the same thing? Pallets are in high demand here… Going for $20 a piece! Trying to find a more affordable option!

Hi Leslie, it is possible I guess, but they might be a little damaged from rain, etc? Ideally you should find used pallets, preferably for free. If you are paying $20 per pallet, you might as well go with some wholesale flooring from Gohaus (or the like).

Is it worth the time/effort to put a tongue/groove joints into your boards or just lay them without? I have about 30×20 foot room to do.

Hi Ken, not really necessary honestly. It would be a little sturdier but if you follow the steps in this guide, you should be fine either way.

Thanks for the flooring guides and advice! My wife wants to put in hardwood floors but we have no idea how to do it ourselves. I think that some kind of floor trusses would look really pretty in our home. We will most likely just hire someone to help us out! Thanks again!

Hi Yilliang! It is a pleasure, hope it all works out for you. Have a good one!

Hi Bill!! Love these floors! My boyfriend and I are turning a school bus into an RV that we can live in full time and want to do pallet wood floors. We’ll be using rigid foam board insulation, but would like to use pallet wood that is as thin as possible. My boyfriend is very tall for a school bus so every 1″ matters…. every 1/4″ matters!! How thin do you think we can go? and how would you recommend doing the sub floor over steel, considering how often we’ll be moving? Thanks so much for all of this great information and for taking the time to respond to everybody! I don’t think I’ve ever seen more responses from the author!

Hi Bri! Sounds like fun, you must send me photos! With pallets, it is a little difficult because you don’t know what type of wood you will find. But you can go a little thinner than outlined in this article, which shouldn’t add much height to the floor, even with the foam underneath. As for sticking it down, sheesh, that is a tricky one. I am leaning towards industrial strength flooring glue so maybe investigate that. Have fun!

Hi Bill, such a lovely article! But i have a couple question, first, i rarely get some hardwoods pallet, pallets in my country using pines wood, do you recommend it for flooring ? and what you think if i just put the pallet using the glue and i dont using my router to make the wood seems like a parquet for flooring ? thanks before, really appreciate your time to reply.

Hi Datu! Thanks for your kind words! Pine is not the best but yes, it can be used for hardwood flooring. I have never done that but I can kind of imagine what you are trying to achieve, should work. I suggest that you try it on a few planks before gluing them, just to make sure you are happy with the appearance. Also, speaking of glue, make sure that it is industrial strength glue that is specifically for this purpose, otherwise it won’t keep it down.

Hi Bill, I love the idea of pallet flooring. I was thinking of using pallet wood since I seen the floors it can produce. Any suggestions since it will be outdoors?

Floor currently is painted plywood.

Thank You for your time.

Hi Debbie! You could use pallets, but just make sure that you seal it properly. Let me know how it goes!

Hi Bill,!im looking at doing pallet floors in a bathroom and hallway? What is the best way to seal for moisture resistance and what type of underlayment is best to use? Thanks.

Hi Mari! Just grab any hardwood floor underlayment, doesn’t have to be super expensive. I have even had a few readers recommend using regular cardboard, although I haven’t personally done that lol. As for the sealant, just ask a local supplier for a decent brand, check the prices and avoid the mid range and cheap options. Remember, you get what you pay for. Hope that helps!

Bill, I love the article! It describes step by step perfectly. I am going to be doing pallet floors and walls in my house in a couple of the rooms and bathroom, however, I am curious about the sealing of the wood. If I use a good quality water sealant, what would be best to put on it so I can use a Swiffer mop? I saw where you said a sealer and full gloss or semi gloss. I am more interested in full gloss so I can get that shine. what is a good brand/product to use for this? I have a lot of foot traffic between 4 kids, 3 adults, and 4 dogs so I need to be able to use a Swiffer on a daily basis. I really appreciate your expertise!

Hi Tiffany! Glad to hear that you liked my article! As for the pallet flooring in the bathroom, I honestly don’t recommend it, as the moisture levels are just too great. Regarding the product, it really depends what is available in your country, and near you hehe. I suggest that you just go for a slightly more expensive one after doing some homework, as you will get what you pay for. Hope that helps a little 🙂

Awesome article! Thank you!

Hi Tyler, it is a pleasure! Glad you liked it, put a lot of effort into it hehe 🙂

Thank you so much for this article. I had laminate down on the kitchen floor of a mobile home. That has since been torn up. I would like to do a pallet kitchen floor but have the cabinets and appliances to contend with. I think I need a bit of direction for this or need to know if it is even doable please. Thank you so much.

Hi Susan, it is definitely doable, but it will take a lot of time and effort. It all depends on if you are willing to do that, as per the points in this article. Alternatively, if it is a small space, often going with a wholesale hardwood provider (as discussed in the blue box on this page) is an easier (and not so expensive) route. Hope that helps.

Hiya, I am installing a palette wood floor in my RV, to live out of. My question is about the floor paper. Would you consider roofing paper for this instead? If not, why not? What is the importance?

Hi Bridget, I haven’t used roofing paper before, but it should work. Heck I have even been told by readers that they have use old six pack boxes (flattened) and its been brilliant so yeah, go for it if you want.

Hello Bill

is there any way that pallets can be used as the supporting structure for flooring eg- putting them down and using yellow tongue as the top of the floor ??

Hi Michelle! It is possible, but you will need to make sure that all the pallet wood is flat. Not saying that isn’t normally the case, but especially so if you are putting something over them. Hope that helps!

Thank you so much for posting this awesome site! I am inspired! I am just wondering if I can sand and stain the boards first to get color variation before I lay them, and then seal?

Hi Naomi, yes you can. Good luck!

Hi Bill I was wondering for finishing a pallet floor do you recommend sanding it all down to even or can the floor be a little different height I was just thinking about using polyurethane on it but how much of a step between the different pallet wood would be too much

Hi Chris! It is really up to you, I prefer a uniform height but that is my preference. I have had a few readers mention that a small difference between them was fine.

What if the pallets are not stamped….can i still use them

Hi Patti, it is completely up to you. In that case, it will be advisable to find out what they were used for in the past (if possible).

I have a bunch of pallet wood I want to use for my kitchen floor… My question is can they be different thickness and sand after it is all down?

Hi Melissa! You can do that, but I recommend that you get yourself a decent sander for the job.

Hi Bill,

What do you think about putting pallet flooring in a bathroom?

Kathy

Hi Kathy! I have had a few readers do it and they loved it, but I personally wouldn’t do it.

I am wanting to put a pallet floor down in my sewing area which is on a concrete pad that currently has linoleum on it. Can I pit the wood down over the linoleum (no damage spots are on it)?

Hi Jennifer! You can if the linoleum is 100% secured (and won’t lift). I would still recommend putting some protective underlayment under the pallet wood though. Good luck!

Do you tounge and groove it first and is it ok to use just regular ol pine

Hi Shawn! If you have the equipment that can do that, go ahead, otherwise yes, it is possible to do it without that process.